Sustainability is becoming more important in construction today as businesses and communities look for ways to reduce environmental impact. One of the key ways to build sustainably is by using recycled steel, which is both eco-friendly and highly durable. Let’s cover the benefits of recycled steel and Butler Manufacturing’s take on sustainable construction.

Why Recycled Steel is the Backbone of Sustainable Construction

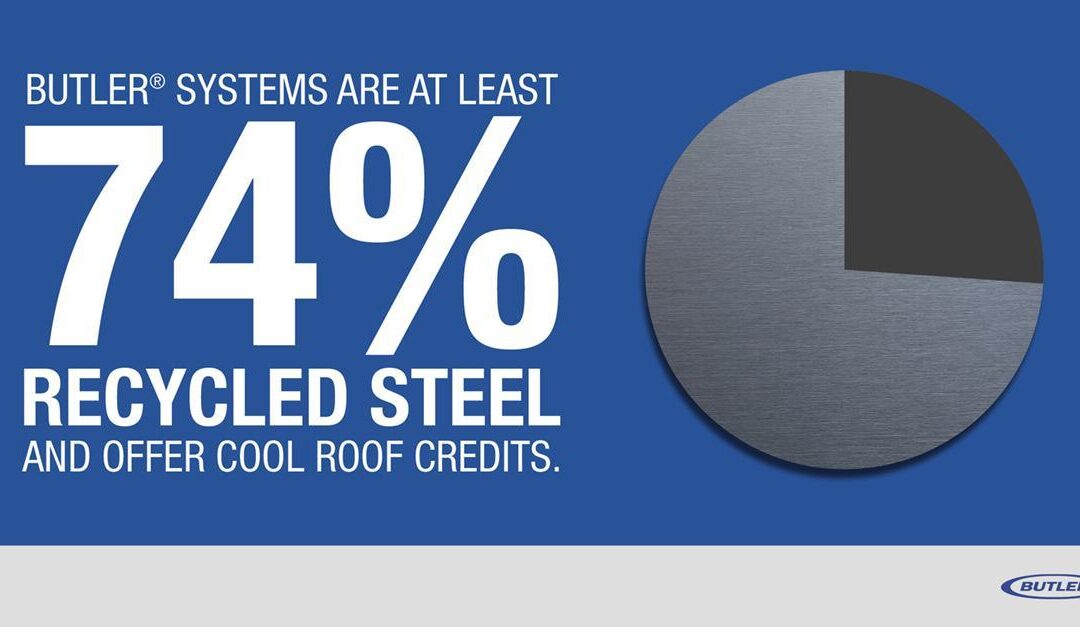

Steel is the most recycled material in the world, with a recycling rate of up to 90% in developed countries. This is because steel can be reused over and over without losing its strength or quality. Every time steel is recycled, it reduces the need for new raw materials, such as iron ore and coal, which are costly to extract and process. Butler Manufacturing leads the way by using up to 74% recycled steel in their buildings. This not only saves natural resources but also lowers the energy required to produce new steel – Recycling steel uses 75% less energy than creating new steel.

Energy Savings and Environmental Benefits

Recycling steel saves a significant amount of energy compared to producing new steel from raw materials.

Every ton of recycled steel saves:

- 2,500 pounds of iron ore

- 1,400 pounds of coal

- 120 pounds of limestone

Butler Manufacturing’s Commitment to Sustainability

Butler Manufacturing has a long-standing commitment to sustainability, and their buildings are designed with the environment in mind. Here’s how Butler leads the way:

- High Recycled Content: Butler’s buildings use up to 74% recycled steel.

- Durability and Longevity: Butler buildings are built to last for decades, reducing the need for replacement and new materials.

- Recyclability: At the end of a building’s life, Butler systems can be easily disassembled and fully recycled.

Butler also offers cool roof finishes, which reflect sunlight and reduce heat absorption. This helps keep buildings cooler, lowering energy costs for businesses. Another key benefit is Butler’s regional manufacturing strategy. With 10 production plants across North America, including nearby locations, Butler reduces transportation emissions and energy use, making their buildings even more eco-friendly.

Reducing Waste with Precision Steel Construction

Recycled steel doesn’t just save resources—it also reduces waste. In traditional construction, materials like wood and concrete create a lot of leftover scrap that ends up in landfills. Steel construction is different:

- Steel is 100% recyclable, meaning nothing is wasted.

- Pre-engineering ensures each component is designed, cut, and assembled with minimal scrap.

- On construction sites, steel generates just 2% waste, compared to 20% waste for wood.

Building Green in Kansas City with MAR Building Solutions

Kansas City is pushing for sustainable growth, and businesses here are looking for construction solutions that align with their environmental goals. MAR Building Solutions, Kansas City’s Butler Builder, helps local companies build smarter, greener, and stronger. Butler’s metal buildings are ideal for Kansas City’s climate, standing up to harsh winters, heavy rain, and high winds while lowering energy use. For local businesses, this means reliable performance, lower maintenance costs, and a positive impact on the environment. Reach out to us to talk about your next project!