When you look at a metal building, you see the steel panels, the framing, and maybe the roofline. But what really keeps that structure standing tall against gravity, wind, snow, and even earthquakes is something invisible: the load path. This hidden highway of forces makes sure every pound of pressure travels safely from the rooftop all the way down into the ground.

Understanding load paths isn’t just important for engineers—it’s critical for builders, contractors, and building owners who want a structure that lasts. And in metal buildings getting the load path right means paying attention to every bolt, clip, and fastener.

What Is a Load Path, Exactly?

These forces include:

- Dead loads (weight of the building materials)

- Live loads (people, furniture, equipment)

- Environmental loads (wind, snow, seismic forces)

- Uplift loads (wind trying to pull the roof off)

Each of these forces has to be collected, directed, and safely delivered into the foundation. The more direct and continuous the path, the better. Interruptions or weak links can cause cracking, sagging, or even collapse.

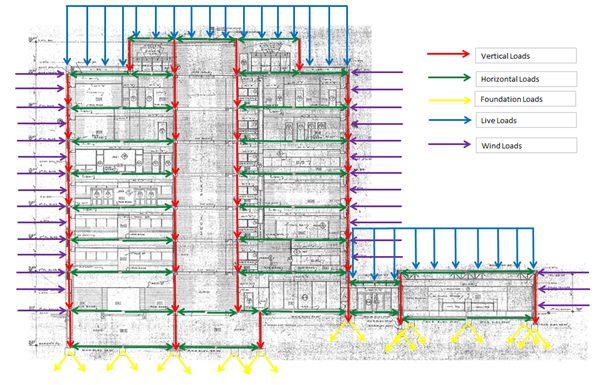

Vertical vs. Horizontal Load Paths

- Vertical load paths carry gravity and uplift forces. For example, the weight of the roof travels through purlins, then rafters or trusses, into columns, and finally to the foundation.

- Horizontal load paths resist side-to-side motion caused by wind or seismic activity. These rely on bracing, diaphragms, and rigid connections to carry forces into vertical frames and down to the ground.

If either of these paths is incomplete or poorly connected, loads can get stuck—or worse, redirected into areas not designed to handle them.

Why Every Bolt Matters

Every structural connection—bolts, welds, fasteners—acts as a link in the load path chain. One loose or missing bolt can compromise the whole system. In fact, the American Institute of Steel Construction (AISC) calls poor load path planning one of the most common sources of engineering errors.

We’re a Butler Builder, so let’s use Butler Manufacturing as an example of lengths that can be gone to to create a solid structure:

Butler systems address this with factory-punched panels, pre-engineered connections, and proprietary fasteners like the Scrubolt™, which has twice the pullout strength of standard screws. These enhancements ensure loads transfer cleanly from one element to the next without guesswork or misalignment.

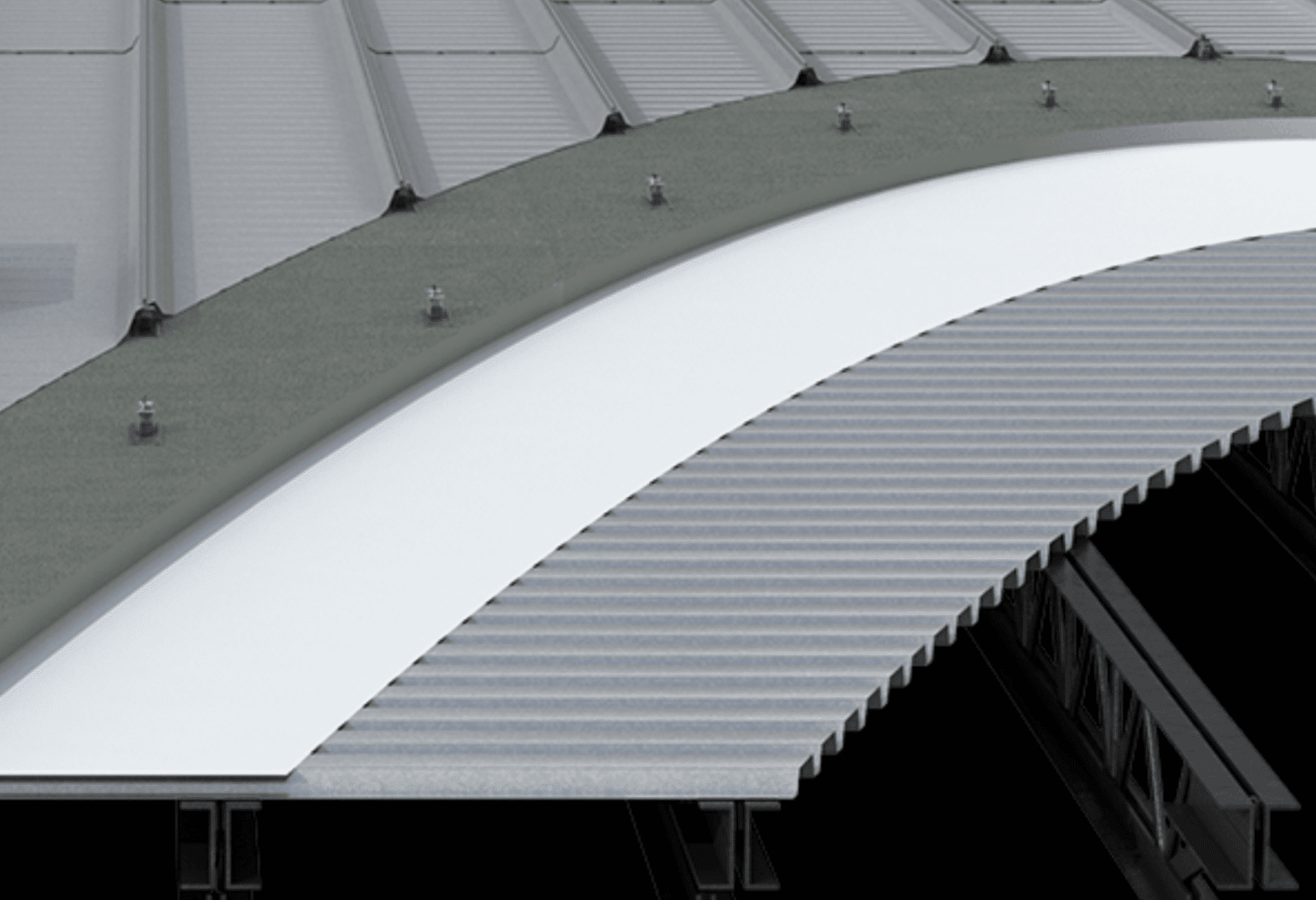

Butler MR-24 Roof System: Engineered for Movement

Metal expands and contracts with temperature changes. If your roof can’t move, the stress will eventually cause leaks or structural damage. The MR-24 roof system solves this with:

- Floating roof clips that allow thermal expansion without breaking the load path

- Pittsburgh double-lock seams that create a watertight connection with 360° of seaming

- Staggered splices placed over structural supports to prevent weak spots

This ensures that the roof load moves exactly where it should—down the columns and into the ground—even as temperatures shift.

Common Load Path Mistakes

- Discontinuous framing: When beams don’t line up vertically with columns, it interrupts the load path.

- Missing connections: A single missed weld or bolt can break the chain.

- Improper bracing: Lateral loads must travel through diaphragms and braced frames.

- Over-reliance on field fixes: Custom drilling in the field often leads to misalignment.

Real-World Forces at Work

Wind uplift is one of the biggest threats to metal buildings. As wind flows over the roof, it creates suction that can pull panels upward. Without a secure load path, this force can rip the roof off.

Butler roof clips and curbs are designed to resist uplift by anchoring panels securely to the structural frame. These clips also allow movement, which prevents tearing or fatigue over time.

Why Load Paths Matter to Building Owners

Getting the load path right means more than meeting code. It means:

- Longer building life

- Fewer maintenance issues

- Better energy efficiency (due to secure insulation and fewer leaks)

- Improved safety and peace of mind

Build Smart from the Ground Up

A strong metal building starts with a solid load path. Every clip, panel, fastener, and bolt is part of a carefully engineered route that keeps your building upright and your investment protected.

Building in Missouri? At MAR Building Solutions, we don’t guess when it comes to load paths. We follow proven systems and combine them with expert installation to make sure your building is rock solid from the roof down.